- Industry news

Industry news

- Category news

Category news

- Reports

- Key trends

- Multimedia

- Journal

- Events

- Suppliers

- Home

- Industry news

Industry news

- Category news

Category news

- Reports

- Key trends

- Multimedia

- Events

- Suppliers

The case for dynamic digital product passports in food supply chains

Key takeaways

- The EU is rolling out Digital Product Passports for durable products to improve traceability and recyclability, while excluding F&B products.

- New academic research argues for dynamic Digital Product Passports for perishable goods to track quality changes and prevent spoilage.

- The approach could cut food waste, improve food safety, and enhance decision-making in F&B.

EU regulators are rolling out Digital Product Passports (DPPs) for shelf-stable products like electronics to make them more traceable across supply chains and elevate their recyclability. However, perishable goods, like food and beverages, have been explicitly excluded.

A new perspective article published in Nature Reviews Clean Technology argues that dynamic DPPS — real-time, intelligent digital records that track the condition of perishable goods — could dramatically cut food waste and improve food safety.

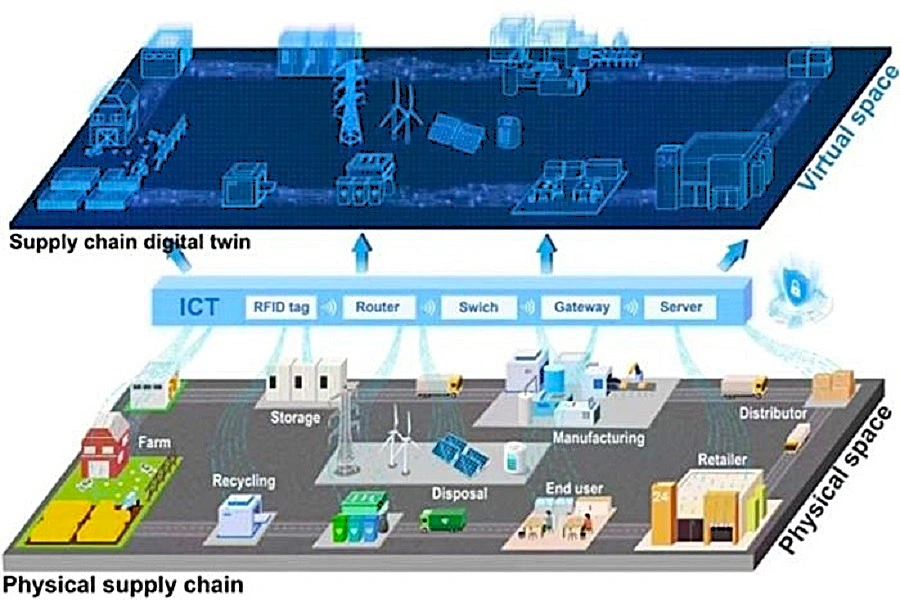

The researchers at the University of Surrey and King’s College London (UK) have introduced what they call the world’s first comprehensive framework for dynamic DPPs, showing how real-time sensing, supply chain digital twins, physics-informed machine learning, and secure data infrastructures can work together to monitor lifecycle changes in short-shelf-life items.

Dynamic DPPs continually update as products move through farms, factories, transport, storage, and retail environments. They could also support earlier interventions to prevent spoilage, reduce unnecessary waste, and strengthen transparency across F&B supply chains.

“Perishable products don’t behave in fixed ways — they change hour by hour as they move through real supply chains, and static DPPs simply cannot keep up,” says Dr. Lei Xing, lecturer in Digital Chemical Engineering at the University of Surrey and lead author.

“We’ve demonstrated how integrating digital twins, real-time sensing, and AI can evolve DPPs from static compliance records into intelligent decision-support tools that enhance safety, cut waste, and enable more circular supply chains.”

“Dynamic DPPs could also help identify where quality begins to decline and why. That knowledge is invaluable for improving stock management and reducing the significant amount of food lost before it ever reaches consumers.”

The economic cost of food waste across the global supply chain is forecast to reach US$540 billion this year, according to the Centre for Economics and Business Research, as the UN’s goal to halve global food waste by 2030 remains in doubt.

New research by Avery Dennison suggests that over a quarter of global retail leaders will not meet the deadline, while meat was found to be the most challenging category for waste. The report encourages F&B firms to view food waste mitigation as a significant business opportunity — not only an ethical and environmental problem.

Dynamic digital product passports

The University of Surrey and King’s College London research also highlights the role of secure, decentralized data systems, such as blockchain-supported networks and smart contract routines, in keeping passport information trustworthy across fragmented supply chains.

Architecture for a digitalized short-shelf-life product supply chain (Image credit: University of Surrey).The team suggests supermarkets could act as “living labs” to test digital DPPs under real conditions, providing a practical way to evaluate how the technology supports freshness monitoring, stock rotation, and day-to-day decision-making.

Architecture for a digitalized short-shelf-life product supply chain (Image credit: University of Surrey).The team suggests supermarkets could act as “living labs” to test digital DPPs under real conditions, providing a practical way to evaluate how the technology supports freshness monitoring, stock rotation, and day-to-day decision-making.

“To make our vision work at scale, DPPs need data infrastructures that can cope with intermittent connectivity and rapidly changing conditions,” explains Dr. Miao Guo, senior lecturer in Engineering at King’s College London and co-creator of the dynamic DPP concept.

“By combining interdisciplinary expertise, our perspective article shows how next-generation networks and secure data architectures can keep product information trustworthy and up-to-date, as short-shelf-life products move through complex, real-world supply chains.”

The researchers say the framework sets out a new pathway for digital sustainability in F&B and shows how collaboration across engineering, AI, and Information and Communication Technology is essential for building safer, smarter supply chains.

EU Digital Product Passports

The EU DPP phases in this year, starting with a small number of high-impact product groups, such as batteries, followed by early Ecodesign for Sustainable Products Regulation categories like textiles, electronics, and furniture, with broader coverage expected through 2028–2030.

The core purpose of DPPs is to embed transparency into products, creating a standardized, digital record of what a product is made of, where it comes from, and how it can be repaired, reused, or recycled. This law shifts sustainability from voluntary claims and labels to verifiable, machine-readable data.

DPPs are widely expected to become crucial to the EU’s circular economy strategy for reducing greenwashing, enabling repair and recycling at scale, and forcing companies to manage product data across the full lifecycle.