- Industry news

Industry news

- Category news

Category news

- Reports

- Key trends

- Multimedia

- Journal

- Events

- Suppliers

- Home

- Industry news

Industry news

- Category news

Category news

- Reports

- Key trends

- Multimedia

- Events

- Suppliers

Angel Yeast trials production at new facility & launches brewing Microbial Pilot Platform

Key takeaways

- Angel Yeast has commenced trial production at its specialty yeast facility, completing its full-chain setup from R&D to large-scale manufacturing.

- The facility features full-process automation to ensure highly sterile conditions and stable, reproducible product quality at scale.

- A new Brewing Functional Microorganism Pilot Test Platform replicates real brewery environments with real-time monitoring and validated solutions that shorten time-to-market for brewers.

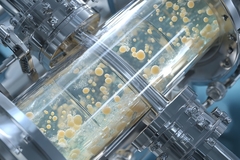

Angel Yeast has started trial production at its specialty yeast project in the Baiyang Biotechnology Park, Yichang High-Tech Zone, China.

The facility commenced material feeding on August 31 and, once fully ramped, will reach an annual capacity of 8,500 metric tons. This launch also completes Angel Yeast’s full-chain layout in specialty yeast — from R&D and pilot-scale production to large-scale manufacturing — enhancing the supply of high-value yeast-derived ingredients for craft brewing, wine, and bioenergy, and strengthening the biomanufacturing value chain.

“The microbiological standard for specialty yeast is at the ten-thousand level, meaning significantly fewer contaminants. Filtered air enters pressurized feeding tanks to maintain positive pressure, ensuring nitrogen, phosphorus, potassium, and other nutrients remain in a highly sterile storage environment,” says Qin Benguo, assistant director of Specialty Yeast Production at Angel Yeast’s Yichang High‑tech subsidiary.

Core lines feature full-process automation, spanning from feeding and fermentation to packaging and storage, which supports stable, reproducible quality at scale.

With a broader application scope than conventional baker’s yeast, Angel Yeast’s specialty yeast targets high-value segments, including craft beer, wine, and other alcoholic beverages, as well as fuel ethanol and biomass energy.

By delivering stable, premium raw materials at scale, the new capacity will enable brewers and bioenergy producers to improve yields, enhance process stability, and achieve flavor and performance consistency — key factors in accelerating product innovation and market expansion.

Brewing a functional microorganism pilot test platform

Complementing its new production line, Angel Yeast has also commissioned its Brewing Functional Microorganism Pilot Test Platform, designed to bridge lab discoveries and industrial‑scale validation.

The platform simulates real-world brewery environments, addressing the limitations of online trials — such as inconsistent operator practices and imprecise timing — by delivering reproducible, data-driven results under factory-like conditions. Equipped with real-time monitoring, it tracks microbial dynamics and the evolution of flavor compounds, enabling precise quality assessment, faster R&D iteration, and optimized technical schemes for partners.

Angel Yeast has started trial production at its specialty yeast project in the Baiyang Biotechnology Park, Yichang High-Tech Zone, China.“Equipped with real‑time monitoring systems, the platform allows us to track microbial dynamics and flavor compound evolution in a controlled, factory-like setting,” explains Luo Xinjie, director of Brewing Technical Support at Angel Yeast’s Food & Fermentation Business Unit. “This enables us to assess product quality with unprecedented precision, refine R&D directions, and optimize technical schemes for our partners.”

Angel Yeast has started trial production at its specialty yeast project in the Baiyang Biotechnology Park, Yichang High-Tech Zone, China.“Equipped with real‑time monitoring systems, the platform allows us to track microbial dynamics and flavor compound evolution in a controlled, factory-like setting,” explains Luo Xinjie, director of Brewing Technical Support at Angel Yeast’s Food & Fermentation Business Unit. “This enables us to assess product quality with unprecedented precision, refine R&D directions, and optimize technical schemes for our partners.”

In the baijiu sector alone, Angel Yeast’s solutions have already helped boost yield, enhance fermentation stability, and enable precise flavor control. With the pilot platform, the cycle from R&D to industrial application can be significantly shortened, allowing breweries to access tailored, validated solutions more quickly — reducing time-to-market and improving operational efficiency.

Together, the 8,500 metric ton specialty yeast facility and the Brewing Functional Microorganism Pilot Platform form what Angel Yeast calls a “powerful engine for global biomanufacturing and brewing innovation.” As the company expands its capabilities from clean, automated specialty yeast production to translational pilot testing, it is poised to deliver more functional, sustainable solutions and inject fresh momentum into bio-based products worldwide.