- Industry news

Industry news

- Category news

Category news

- Reports

- Key trends

- Multimedia

- Journal

- Events

- Suppliers

- Home

- Industry news

Industry news

- Category news

Category news

- Reports

- Key trends

- Multimedia

- Events

- Suppliers

Fi Europe Innovation Awards 2025: Future foodtech finalists target efficiency, stability and cost reduction in F&B

Key takeaways

- In its Future Foodtech Innovation Award, Fi Europe 2025 spotlights advancements in plant-based performance, AI-driven formulation, and whole-oat processing.

- AI is reshaping product development, as finalist AKA Food’s platform speeds formulation, cuts experimentation, and boosts prototype success.

- Other finalists Amano and Tetra Pak deliver technical leaps, from enzymes that stabilize plant proteins to whole-oat lines that boost protein, fiber, and efficiency.

Food Ingredients First continues its series of in-depth explorations of award finalists with a preview of the Future Foodtech Innovation Award contenders at Fi Europe 2025. The spotlight falls on technologies redefining plant-based performance, AI-powered product development, and whole-oat beverage processing as the industry prepares for the celebration and awards ceremony on December 2 in Paris, France.

The finalists are Amano Enzyme (Plants Unlimited platform for clean label enzyme solutions), AKA Food (AI-based Intelligence Platform for application development), and Tetra Pak (whole oat beverage lines).

Companies are witnessing an increase in consumer interest in food tech innovations driven by AI. Innova Market Insights research suggests that nearly 41% of consumers globally see potential in using AI to develop F&B products, driving innovators to utilize the technology to fast-track innovation, accelerate R&D, and interpret trends earlier than traditional methods.

Plant-based advancements are reshaping indulgence through ice cream applications, exploring high-protein and enhanced textures in alternative dairy products. Manufacturers are also tapping hybrid systems to enhance the texture, creaminess, and stability of dairy alternatives to meet clean label and sustainability demands.

AKA Foods: Intelligence Platform

Dutch food tech firm AKA Foods’ Intelligence Platform for Application Development integrates critical data sources and uses AI to help application development professionals in pitching innovative concepts, product prototypes, and solutions in response to customer demands.

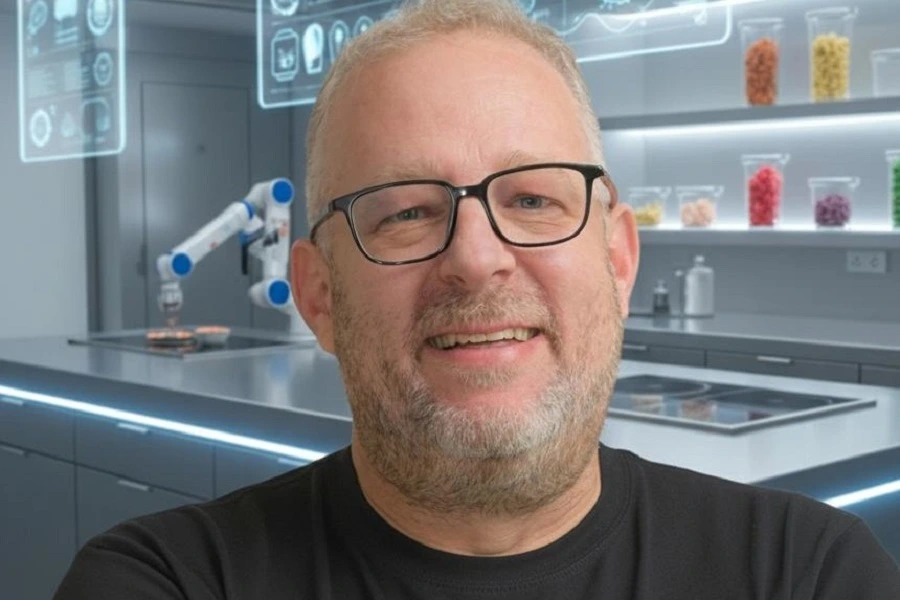

AKA Foods’ Intelligence Platform helps teams cut redundant experiments and reach validated prototypes faster, says CEO David Sack.“The inspiration came from combining two lived perspectives. People on our team have worked in food R&D themselves, and saw first-hand how much expertise was segmented into spreadsheets, sensory reports, and old project files,” David Sack, AKA’s Foods’ founder and CEO, tells Food Ingredients First.

AKA Foods’ Intelligence Platform helps teams cut redundant experiments and reach validated prototypes faster, says CEO David Sack.“The inspiration came from combining two lived perspectives. People on our team have worked in food R&D themselves, and saw first-hand how much expertise was segmented into spreadsheets, sensory reports, and old project files,” David Sack, AKA’s Foods’ founder and CEO, tells Food Ingredients First.

The platform differs from generic AI tools, which cannot understand formulations, ingredient functionality, or sensory impact. However, AKA Studio, a secure AI-powered SaaS platform for food innovation developed by the company, can, “because it is built on a unified food syntax that gives the system a real language for product development,” Sack explains.

“The Food Specific AI Assistant can reason with a company’s own data, connect to its external sources, and support decisions across formulation and sensory workflows. Everything runs inside a private, secure environment, which is essential when dealing with proprietary recipes and processes.”

The team measures the platform’s impact by tracking time-to-market improvements, reduced redundant experiments, and higher formulation success rates. These metrics show how quickly teams can move from brief to validated prototype and reach a stable, consumer-ready product when adapting or optimizing recipes.

The AI platform is currently in the early stages, and adoption among manufacturers and ingredient companies is growing through paid deployments and pilot programs. The present focus is on the core product development workflows, where the impact is most immediate.

AKA Foods’ Food Specific AI Assistant can reason with a company’s own data and guide formulation and sensory decisions.“From there, the roadmap naturally expands into areas such as scale up, production planning, and operational decision support. The long-term vision is a structured, intelligent environment that supports more of the lifecycle beyond formulation and sensory work,” Sack adds.

AKA Foods’ Food Specific AI Assistant can reason with a company’s own data and guide formulation and sensory decisions.“From there, the roadmap naturally expands into areas such as scale up, production planning, and operational decision support. The long-term vision is a structured, intelligent environment that supports more of the lifecycle beyond formulation and sensory work,” Sack adds.

Tetra Pak: Whole oat beverage lines

Tetra Pak’s whole oat beverage lines use 100% of oat grain, compared to the usual 80%.

“Our ambition was to enable producers to use the entire oat kernel in the final product, while minimizing operational costs, reducing water usage, and eliminating the burdensome waste handling associated with traditional oat processing,”a Tetra Pak spokesperson tells us.

The beverage line delivers “over 25% higher throughput” from the same amount of raw material, significantly reducing the land required for oat cultivation.

While developing the line, the team faced challenges in ensuring efficient reduction of the particle size of the remaining non-soluble components in the final beverage.

“When starting the project we already had the experience of achieving this with soybeans (our whole-bean solutions are already used by several producers of whole soy beverages and fermented products),” adds the spokesperson.

Tetra Pak’s whole oat beverage line delivers 25% higher throughput from the same amount of oats to improve raw material efficiency.“However, oats presented a much greater challenge. Oat grains require significantly more shear and a more advanced, multi-step approach. To overcome this, we conducted extensive trials in our plant-based pilot plant to determine the optimal design for both the overall line and key equipment components.”

Tetra Pak’s whole oat beverage line delivers 25% higher throughput from the same amount of oats to improve raw material efficiency.“However, oats presented a much greater challenge. Oat grains require significantly more shear and a more advanced, multi-step approach. To overcome this, we conducted extensive trials in our plant-based pilot plant to determine the optimal design for both the overall line and key equipment components.”

The concept has been very well received by the industry, and manufacturers are now actively tailoring their oat products to this approach in the company’s Product Development Centers.

“We anticipate these products will soon move into commercial launch and appear on retail shelves for everyone to enjoy products with 200% more fiber and 60% more protein compared with conventional oat beverages,” notes the spokesperson.

Amano Enzyme: Plants Unlimited

Japan-based Amano Enzyme’s Plants Unlimited is a next-generation platform delivering targeted, clean label “specialty” enzyme solutions for plant-based innovation, Atsushi Tanaka, VP, EMEA at Amano Enzyme, tells us.

“Our development of the Plants Unlimited platform was inspired by the need to bridge the gap between consumer expectations and the reality of plant-based food and beverage options. A primary challenge we observed was the instability of plant-based drinks, which would often curdle when added to hot coffee or other acidic beverages, unlike their dairy counterparts.”

To solve this, the company developed Protein Glutaminase “Amano” 500 (PG500), which stabilizes plant proteins and boosts foam capacity and stability.

“Our key differentiator lies in the extensive scientific research and dedicated technical support that accompany our products,” says Tanaka. “For example, our PG500 enzyme is supported by over 70 patents and has been featured in 10 peer-reviewed journal articles. All of our enzymes for plant-based applications are organic and non-GM.”

He highlights developing solutions for sugar reduction in plant-based beverages “without compromising the taste and texture that consumers expect” as the biggest formulation challenge.

Amano Enzymes’ PG500 enzymes ensure plant-based drinks remain smooth and curdle-free when added to hot coffee (Image credit: Amano Enzymes).“This led to the development of our Kleistase, Veramax G2, and Veramax G3 enzymes. The key insight from this process was that by focusing on the inherent potential of the plant-based ingredients themselves, we could create solutions that not only met but exceeded the functional and sensory profiles of traditional products.”

Amano Enzymes’ PG500 enzymes ensure plant-based drinks remain smooth and curdle-free when added to hot coffee (Image credit: Amano Enzymes).“This led to the development of our Kleistase, Veramax G2, and Veramax G3 enzymes. The key insight from this process was that by focusing on the inherent potential of the plant-based ingredients themselves, we could create solutions that not only met but exceeded the functional and sensory profiles of traditional products.”

The company measures the impact of its enzyme solutions through a combination of “rigorous internal testing” and the success of its customers in the marketplace by means of cost savings, improved production efficiency, and enhanced sensory characteristics of the final consumer product.

The platform is now in full commercial rollout, with clients across Europe and North America launching products that utilize Amano’s enzymes.

“Our next steps are to continue to expand the capabilities of the Plants Unlimited platform by developing new enzymes for other plant protein sources and emerging categories, such as plant-based yogurts and desserts,” Tanaka concludes.

Last week, we examined F&B innovations by finalists in the Dairy Alternative Innovation Award and Sustainability Innovation Award categories.